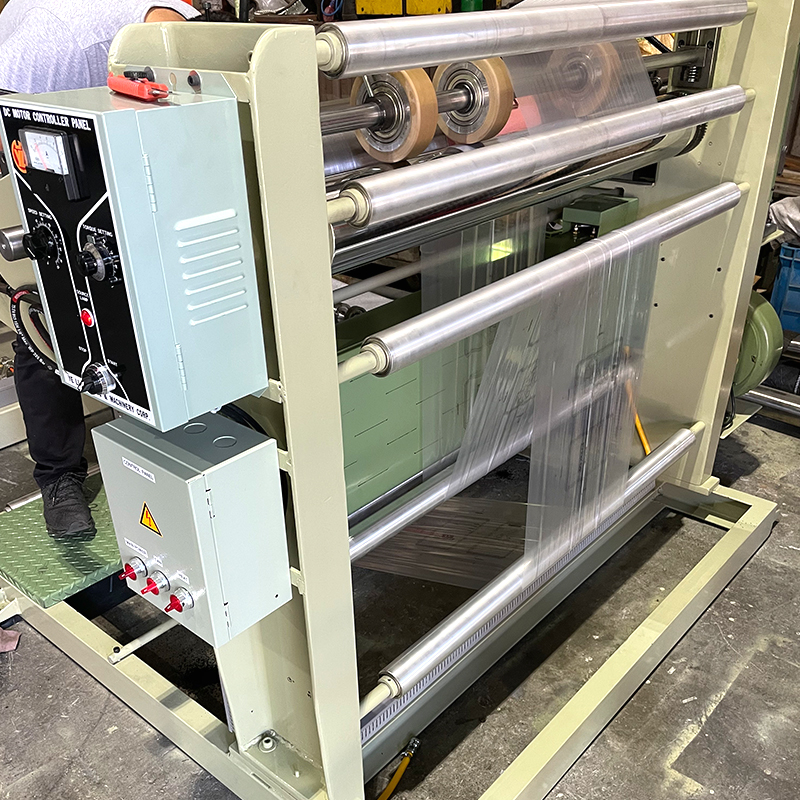

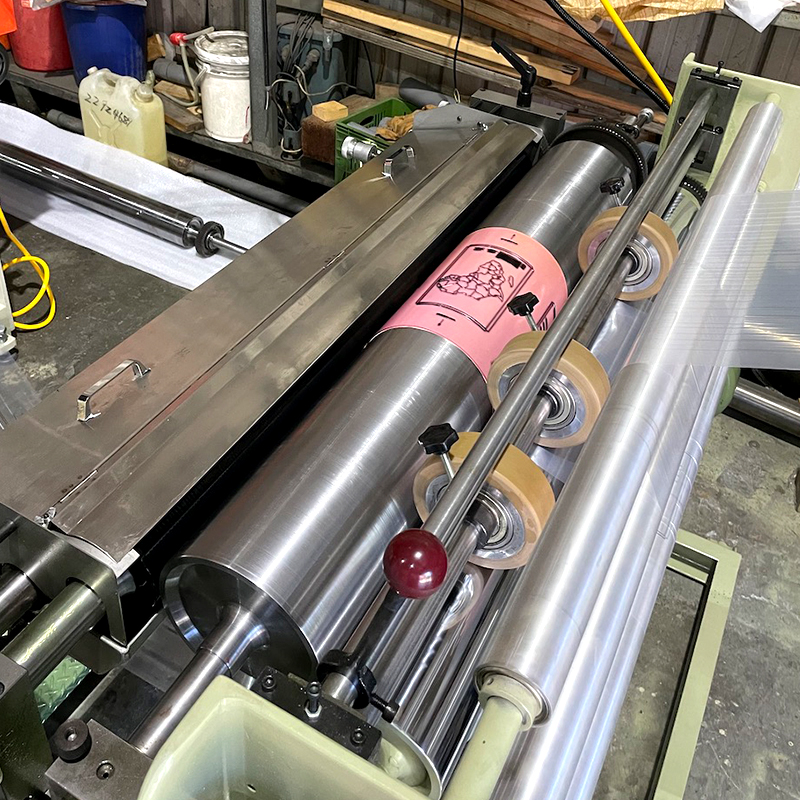

Inline (online) 1-2 Color press used with blown-film extruder.

Pneumatic Controls for ease of operation.

Machine will not need installation. Near plug and play.

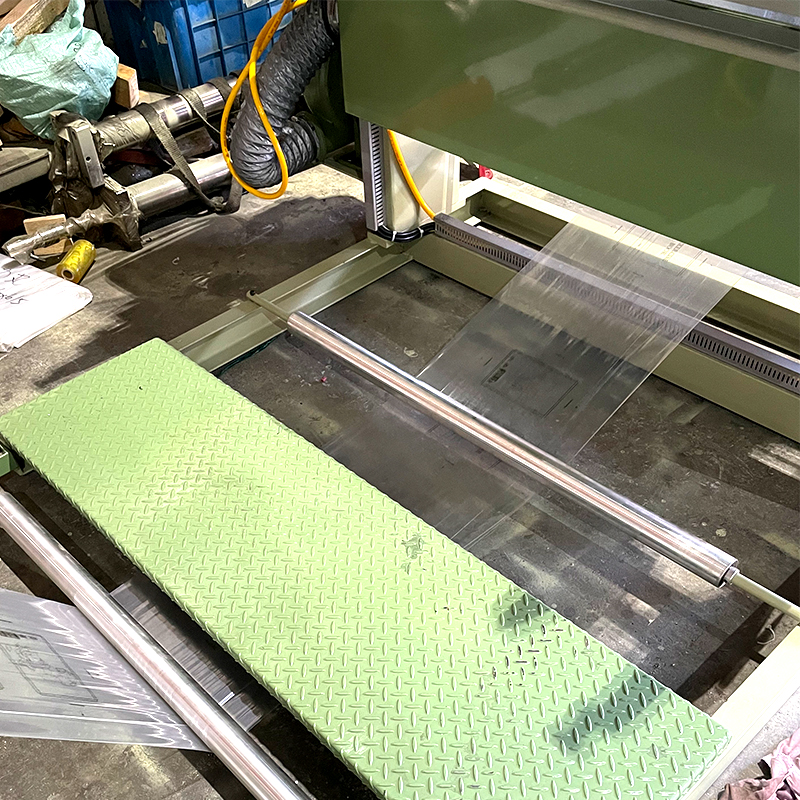

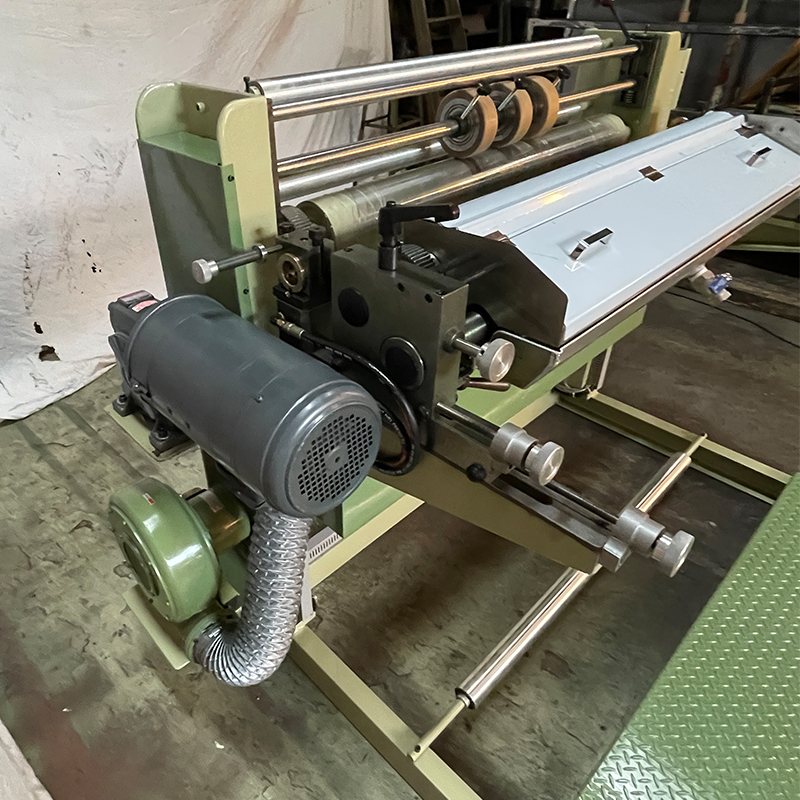

VISUAL ASPECT

TECHNICAL DATA

NAME | LY-1060 | LY-1080 | LY-1100 | LY-1120 | LY-1140 |

WEB WIDTH | 600 MM | 800 MM | 1000 MM | 1200 MM | 1400 MM |

MAIN MOTOR | 1/2 HP DC TORQUE | 1 HP DC TORQUE | 1 HP DC TORQUE | 2 HP DC TORQUE | 2 HP DC TORQUE |

HEATER BLOWER | 1/2 HP AC | 1/2 HP AC | 1 HP AC | 1 HP AC | 1-1/2 HP AC |

PLATE CYLINDER | PNEUMATIC SYSTEM | “ ” | “ ” | “ ” | 1-1/2 HP AC |

HEATER | 3 KW | 3 KW | 4.5 KW | 4.5 KW | 6 KW |

MAX ROLL DIA. | 850 MM | 1000 MM | 1000 MM | 1000 MM | 1000 MM |

MAX PRINT WIDTH | 550 MM | 750 MM | 950 MM | 1150 MM | 1350 MM |

MAX OUTPUT | 70 M/MIN | “ ” | “ ” | “ ” | “ ” |

DIMENSIONS | 180X150X150 | 180X170X150 | 180X180X150 | 190X200X150 | 205X220X150 |