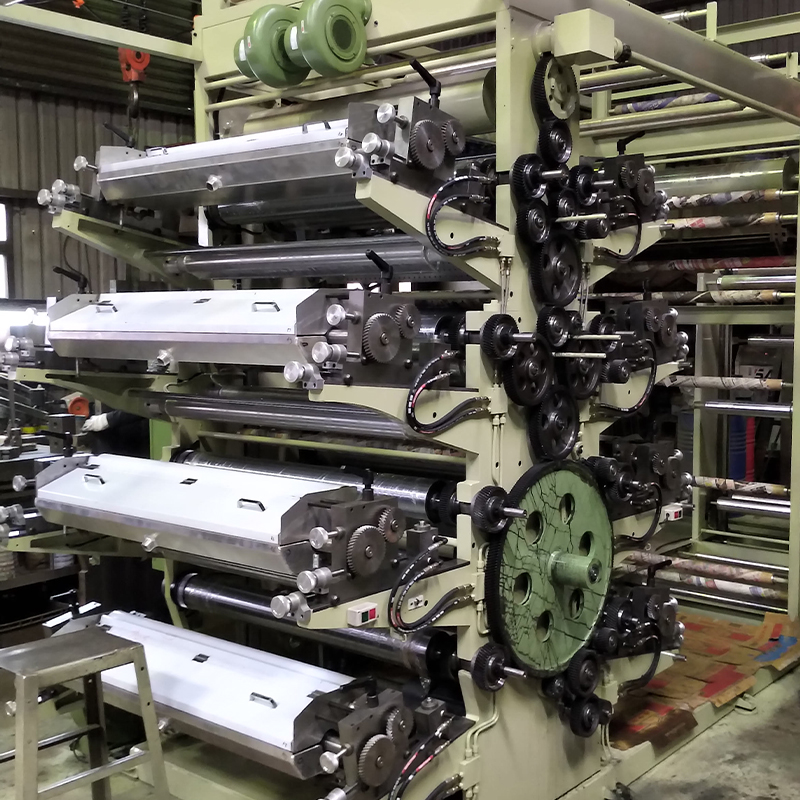

High speed chamber doctor blade press with automated systems for next level photo-quality ready prints.

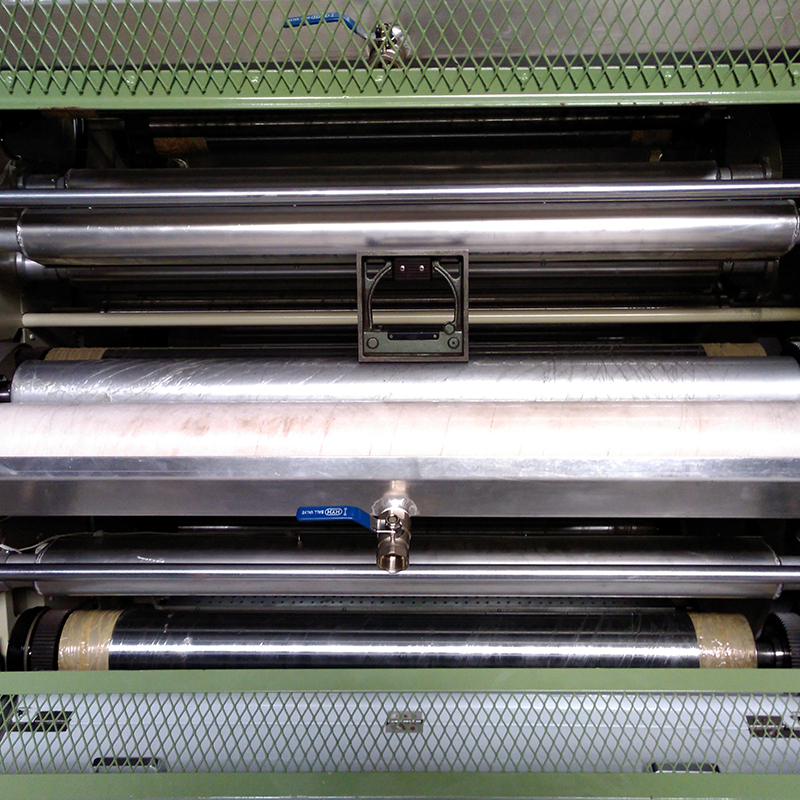

Ink-saving technology is incorporated to maximize company profits

Inspection system upon finishing, allows operator to seamlessly check for jobs processed.

VISUAL ASPECT

TECHNICAL DATA

NAME | LY-6080DX-DB | LY-6100DX-DB | LY-6120DX-DB | LY-6140DX-DB |

WEB WIDTH | 800 MM | 1080 MM | 1280 MM | 1480 MM |

MAIN MOTOR | 5 HP AC INVERTER | 7-1/2 HP AC INVERTER | 7-1/2 HP AC INVERTER | 10 HP AC INVERTER |

INK REDUCER | 1/2 HP AC | 1 HP | 1 HP | 1-1/2 HP |

CIRCULATION | 2 HP AC | 2 HP AC | 2 HP AC | 2-1/2 HP AC |

OVERHEAD/OVEN | 2 HP AC | 2 HP AC | 2 HP AC | 2-1/2 HP AC |

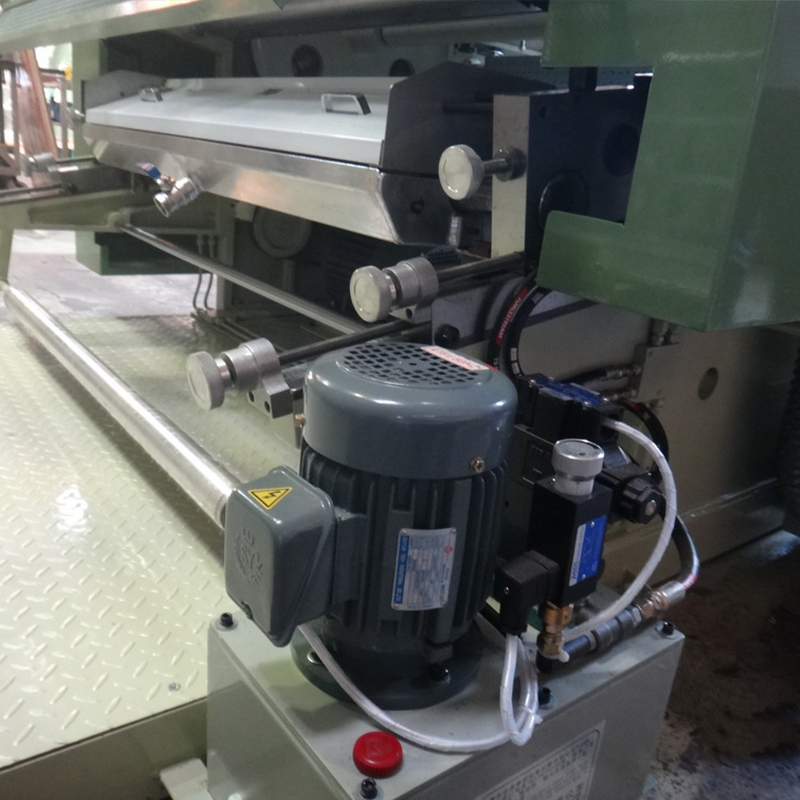

PLATE CYLINDER | HYDRAULIC SYSTEM | “ ” | “ ” | “ ” |

HEATER | 18 KW | 21 KW | 24 KW | 25.5 KW |

PRINT COMBINATION | 6+0 / 5+1 / 4+2 / 3+3 | “ ” | “ ” | “ ” |

MAX ROLL DIA. | 1000-1500 MM | 1000-1500 MM | 1000-1500 MM | 1000-1200 MM |

MAX PRINT WIDTH | 780 MM | 980 MM | 1180 MM | 1380 MM |

MAX OUTPUT | 150 M/MIN | “ ” | “ ” | “ ” |

CUBIC METER | 560X175X275 | 595X195X275 | 630X215X275 | 665X250X275 |

OPTIONS

Tension control for the unwind

Feeds substrate material nicely into the operation without potentially damaging the substrate.

Increase print quality with greater control of material tension.

EPC (Edge Positioning Control)

Guide substrate material uniformly into the print operation.

Best with irregularities of film edge after blow-film extrusion process. This step guides the substrate roll back to uniformity.

Superior Drying System

Increased productivity with increased speed of ink drying.

Not recommended for electricity-consumption conscious productions