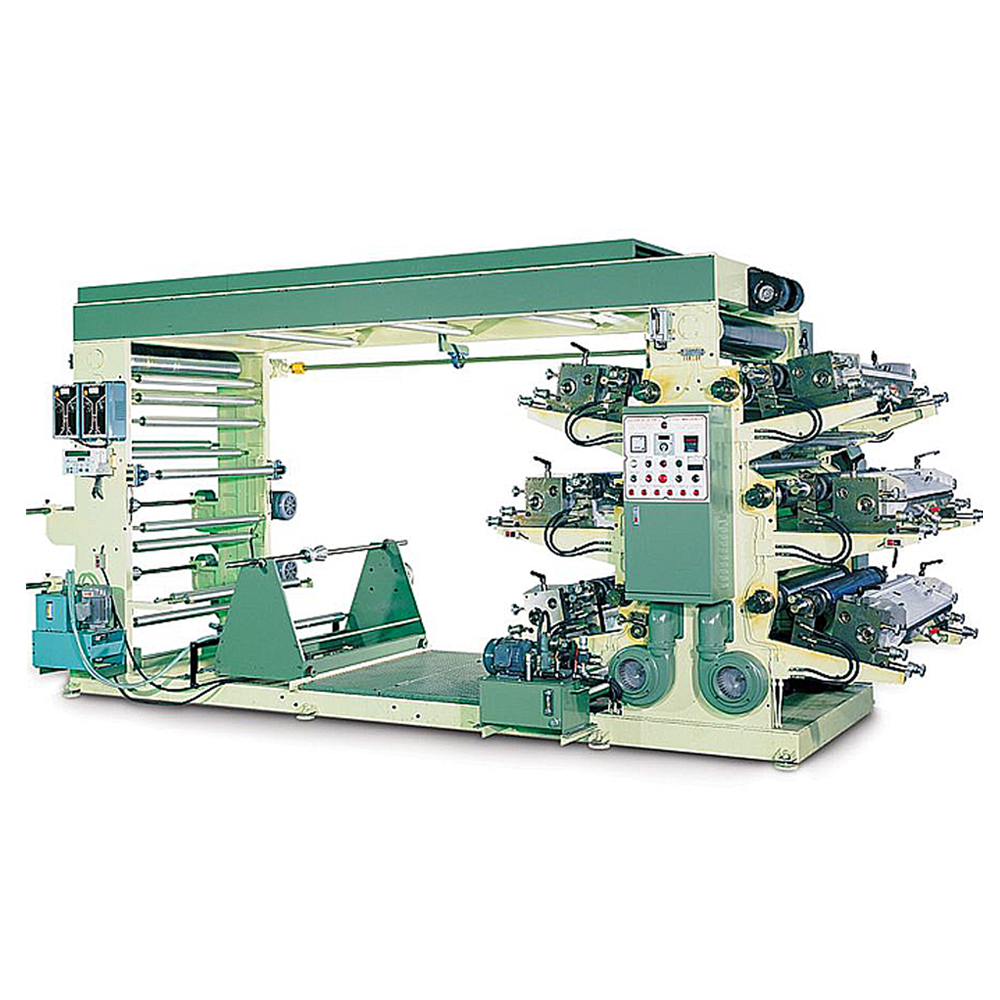

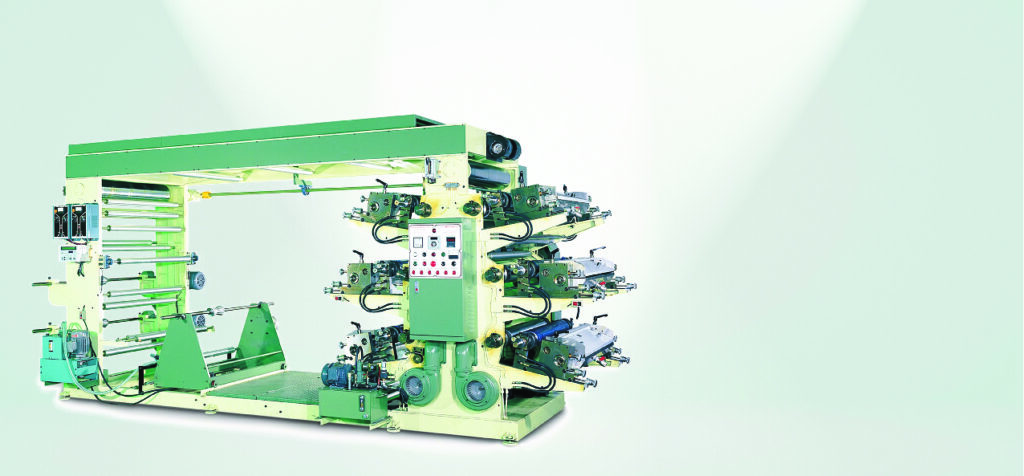

4 SERIES

1.Compact type Deluxe model press with ex- cellent quality for printing on paper, film, woven and non-woven roll materials.

2.Centeralized handle pressure lubrication system for impression roller’s joint.

3.Reverse printing web threading through bottom base idling rollers for longer distance drying without reducing the printing speed.

STYLE

| LY-4120 | LY-4060 | LY-4080 | LY-4100 | LY-4120 | LY-4140 |

| WEB WIDTH | 600 MM | 800 MM | 1000 MM | 1200 MM | 1400 MM |

| MAIN MOTOR | 3 HP AC Inverter | 3 HP AC Inverter | 5 HP AC Inverter | 5 HP AC Inverter | 7-1/2 HP AC Inverter |

| INK REDUCER | 1/2 HP AC | 1 HP | 1/2 HP | 1 HP | 1 HP |

| CIRCULATION | 1/2 HP AC | 1/2 HP AC | 1 HP AC | 1-1/2 HP AC | 1-1/2 HP AC |

| OVERHEAD/OVEN | 1/2 HP AC | 1/2 HP AC | 1 HP AC | 1-1/2 HP AC | 1-1/2 HP AC |

| PLATE CYLINDER | Hydraulic system | Hydraulic system | Hydraulic system | Hydraulic system | Hydraulic system |

| HEATER | 9 KW | 9 KW | 12 KW | 15 KW | 18 KW |

| PRINT COMBINATION | 4+4 / 3+1 / 2+2 | 6+6 / 5+1 / 4+2 / 3+3 | 6+6 / 5+1 / 4+2 / 3+3 | 6+6 / 5+1 / 4+2 / 3+3 | 6+6 / 5+1 / 4+2 / 3+3 |

| MAX ROLL DIA. | 650-1000 MM | 650-1000 MM | 800-1000 MM | 800-1000 MM | 800-1000 MM |

| MAX PRINT WIDTH | 550 MM | 750 MM | 950 MM | 1150 MM | 1340 MM |

| MAX OUTPUT | 60 M/MIN | 60 M/MIN | 60 M/MIN | 60 M/MIN | 60 M/MIN |

| CUBIC METER | 400X175X200 | 400X195X210 | 400X215X210 | 400X250X210 | 400X270X210 |

OPTIONS

Tension control for the unwind

Feeds substrate material nicely into the operation without potentially damaging the substrate.

Increase print quality with greater control of material tension.

EPC (Edge Positioning Control)

Guide substrate material uniformly into the print operation.

Best with irregularities of film edge after blow-film extrusion process. This step guides the substrate roll back to uniformity.

Superior Drying System

Increased productivity with increased speed of ink drying.

Not recommended for electricity-consumption conscious productions